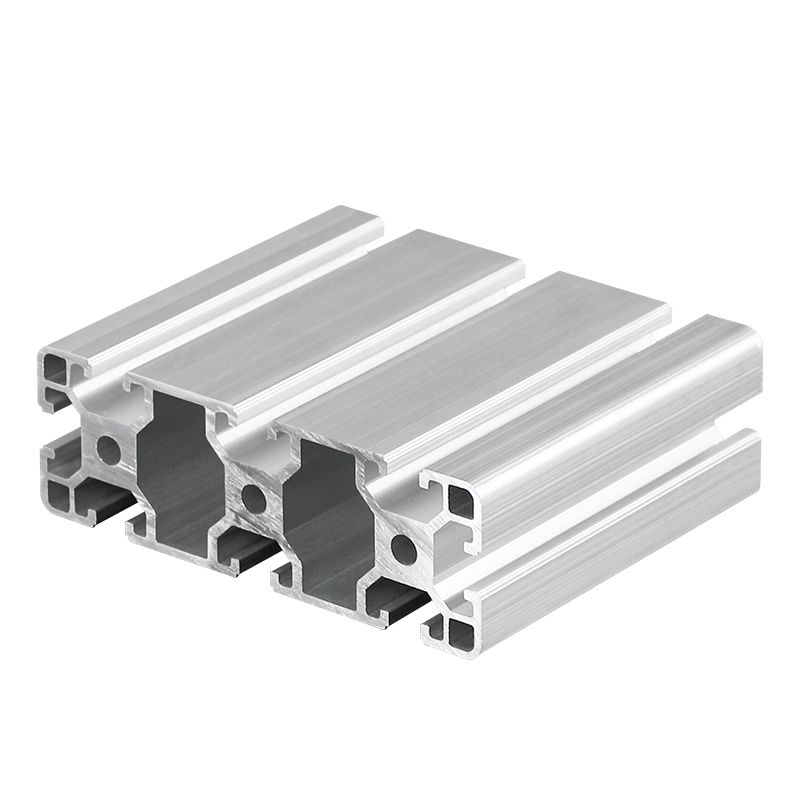

High-Quality Aluminium Profile for Various Applications

By:Admin

In recent years, the demand for aluminum profiles has been steadily increasing in various industries such as construction, transportation, electronics, and more. As a result, companies have been striving to develop innovative and high-quality aluminum profiles to meet the evolving needs of their customers. One such company that is at the forefront of this revolution is [Company Name].

[Company Name] is a leading manufacturer of aluminum profiles, dedicated to providing exceptional products and services to its clients. With cutting-edge technology and a team of skilled professionals, the company has been able to stay ahead of the competition and consistently deliver top-notch aluminum profiles to its customers.

The latest innovation by [Company Name] is the H Aluminum Profile, a product that is set to revolutionize the metal industry. This new profile is designed to offer superior strength, flexibility, and durability, making it suitable for a wide range of applications. Its unique H-shaped cross-section provides excellent load-bearing capacity, making it ideal for structural and architectural purposes. Moreover, the profile can be customized to meet specific design requirements, giving architects, engineers, and designers the flexibility to bring their creative visions to life.

One of the key features of the H Aluminum Profile is its lightweight nature, which makes it easy to handle and transport. This characteristic not only simplifies the installation process but also contributes to reducing overall material and transportation costs. Additionally, the profile is corrosion-resistant, ensuring that it can withstand harsh environmental conditions, making it a reliable choice for outdoor applications.

Another advantage of the H Aluminum Profile is its sustainability. Aluminum is a fully recyclable material, and by choosing aluminum profiles, customers can contribute to the global effort to reduce waste and minimize the environmental impact. With the increasing emphasis on sustainable practices, the H Aluminum Profile is a testament to [Company Name]'s commitment to environmental responsibility.

The versatility of the H Aluminum Profile is another reason for its growing popularity. It can be used in a myriad of applications, including the construction of glass facades, curtain walls, solar panel frames, industrial equipment, transportation vehicles, and more. The profile can also be anodized or powder-coated in various colors to enhance its aesthetic appeal, allowing it to seamlessly blend with different design styles.

Furthermore, [Company Name] places a strong emphasis on quality control and precision engineering, ensuring that every batch of H Aluminum Profile meets stringent industry standards. The company's state-of-the-art manufacturing facilities and rigorous testing procedures guarantee that customers receive a product of exceptional quality, reliability, and consistency.

"With the introduction of the H Aluminum Profile, we aim to provide our customers with a superior solution for their metal shaping needs," says [Spokesperson's Name], [Position] of [Company Name]. "We are committed to pushing the boundaries of innovation and excellence, and we believe that the H Aluminum Profile is a testament to our dedication to delivering cutting-edge products to the market."

In conclusion, the H Aluminum Profile by [Company Name] is set to redefine the capabilities of aluminum profiles, offering an unmatched combination of strength, flexibility, durability, and sustainability. As industries continue to evolve and demand higher-performing materials, the H Aluminum Profile stands out as a game-changer, meeting the needs of architects, engineers, designers, and manufacturers across various sectors. With its myriad advantages and the backing of [Company Name]'s expertise, the H Aluminum Profile is poised to make a significant impact on the metal industry for years to come.

Company News & Blog

Aluminium Frame Unveiled as Latest Modular Innovation in Construction

Modular Aluminium Frame Revolutionizing the Construction IndustryThe construction industry has seen a significant shift in recent years with the introduction of innovative building materials and techniques. One such innovation that is making waves in the industry is the Modular Aluminium Frame, a game-changer for construction projects around the world.The Modular Aluminium Frame, produced by [Company], is a versatile and cost-effective solution for building structures of all kinds. It is designed to be lightweight, durable, and easily customizable, making it an ideal choice for a wide range of construction applications. The frame is made from high-quality aluminium, which not only makes it strong and long-lasting but also ensures that it is resistant to corrosion and other environmental factors.One of the key benefits of the Modular Aluminium Frame is its modular design, which allows for easy assembly and disassembly. This means that construction projects can be completed more quickly and efficiently, saving both time and money. The frame can be customized to fit the specific requirements of a project, making it a versatile and adaptable solution for any construction need.In addition to its versatility, the Modular Aluminium Frame is also an environmentally friendly option for construction. Aluminium is a highly recyclable material, and the production of the frame has a significantly lower carbon footprint compared to traditional building materials. This makes it an attractive choice for companies looking to reduce their environmental impact and promote sustainable construction practices.[Company] has been at the forefront of developing and manufacturing the Modular Aluminium Frame, and their commitment to quality and innovation has made them a trusted name in the industry. With a team of expert engineers and designers, the company is constantly pushing the boundaries of what is possible in construction, creating new solutions that are revolutionizing the way buildings are made.The company's dedication to excellence extends to its customer service and support, ensuring that clients have access to the resources and expertise they need to make the most of the Modular Aluminium Frame. From initial design and planning to final installation, [Company] is committed to providing top-notch service to their clients, establishing long-term relationships built on trust and mutual success.The impact of the Modular Aluminium Frame is being felt across the construction industry, with an increasing number of projects opting for this innovative building solution. From residential homes to commercial buildings and industrial facilities, the versatility and cost-effectiveness of the frame make it an attractive choice for a wide range of applications.In conclusion, the Modular Aluminium Frame is a game-changing innovation in the construction industry, offering a versatile, cost-effective, and environmentally friendly solution for building structures of all kinds. With [Company] leading the way in its development and manufacturing, the frame is poised to revolutionize the way buildings are made, delivering efficiency, sustainability, and quality to construction projects around the world.

Aluminum Extrusion Manufacturer Produces High-Quality Products for Various Industries

KJN Extrusion, a leading company in the field of aluminum extrusion, has been making waves in the industry with its innovative technologies and top-quality products. The company, which was founded in 1993, has established itself as a global leader in aluminum extrusion and has continuously strived to push the boundaries of what is possible in the field.KJN Extrusion has made a name for itself by delivering high-quality aluminum extrusion products to a wide range of industries, including automotive, aerospace, construction, and electronics. The company's dedication to excellence and commitment to innovation have set it apart from its competitors, and it has become a trusted partner for many businesses looking for top-tier aluminum extrusion solutions.One of the key factors that have contributed to KJN Extrusion's success is its investment in cutting-edge technologies. The company has continually invested in state-of-the-art equipment and processes, allowing it to produce aluminum extrusions that are of the highest quality while also being cost-effective. This commitment to technological advancement has allowed KJN Extrusion to stay ahead of the curve and maintain its position as a leader in the industry.In addition to its focus on technology, KJN Extrusion is also known for its dedication to sustainability. The company has implemented environmentally friendly practices throughout its operations, ensuring that its manufacturing processes have minimal impact on the environment. This commitment to sustainability has not only helped KJN Extrusion reduce its carbon footprint but has also positioned it as a responsible and forward-thinking company in the eyes of its customers and partners.KJN Extrusion's success can also be attributed to its strong focus on customer satisfaction. The company prides itself on providing excellent customer service and is committed to meeting the needs of its clients. By maintaining open communication with its customers and being responsive to their needs, KJN Extrusion has built lasting relationships with a diverse range of clients across different industries.Recently, KJN Extrusion made headlines with the introduction of a groundbreaking new extrusion technology. The company's R&D team has developed a state-of-the-art extrusion process that allows for the production of complex and intricate aluminum profiles with unprecedented precision. This new technology has the potential to revolutionize the industry, opening up a myriad of new possibilities for the use of aluminum extrusions in various applications.The innovative extrusion technology developed by KJN Extrusion has already garnered significant interest from companies in the automotive and aerospace industries, as well as from architectural and design firms. The ability to create highly complex and precise aluminum profiles has the potential to drive significant advancements in these industries, offering new possibilities for lightweight and durable components.Furthermore, the new extrusion technology is also expected to have a positive impact on the company's bottom line. By offering unique and advanced extrusion solutions, KJN Extrusion is positioning itself as a preferred partner for businesses looking to stay ahead of the competition and gain a competitive edge in their respective markets.With its cutting-edge technology, commitment to sustainability, and dedication to customer satisfaction, KJN Extrusion is poised to continue leading the way in the aluminum extrusion industry. The company's innovative spirit and passion for excellence have enabled it to thrive in a competitive market, and its latest advancements in extrusion technology are a testament to its ongoing commitment to pushing the boundaries of what is possible in the field. As KJN Extrusion continues to innovate and evolve, it is expected to remain a key player in the industry for many years to come.

High-Quality and Sustainable Aluminium Profile for a Wide Range of Applications

[Company Name], a leading manufacturer in the aluminum industry, has recently launched a new product – the innovative 1515 Aluminium Profile. This new profile offers a wide range of applications and features that cater to various industries' needs. The company's commitment to excellence and innovation in the aluminum sector has made them a trusted name in the industry.The 1515 Aluminium Profile is a versatile and durable solution for construction, machinery, transportation, and other industrial applications. Its high-strength aluminum material makes it ideal for structural support and framing in a wide range of projects. The profile is designed to withstand heavy loads and harsh environmental conditions, making it suitable for both indoor and outdoor use.One of the key features of the 1515 Aluminium Profile is its easy assembly and customization options. The T-slot design allows for quick and easy installation of accessories and fittings, making it simple to adapt to different project requirements. This flexibility makes it highly adaptable for a wide range of applications, as it can be easily modified and reconfigured as needed.In addition to its versatility, the 1515 Aluminium Profile also offers excellent corrosion resistance and low maintenance requirements, ensuring long-term durability and reliability. This makes it an ideal choice for applications that require a reliable and long-lasting solution, such as infrastructure and industrial machinery.The launch of the 1515 Aluminium Profile underscores [Company Name]'s dedication to meeting the evolving needs of the aluminum industry. The company has a strong track record of delivering high-quality products that meet the strictest standards for performance and reliability. With a focus on advanced manufacturing techniques and continuous improvement, [Company Name] is well-positioned to deliver cutting-edge solutions to their customers.The 1515 Aluminium Profile is just one example of [Company Name]'s commitment to innovation and excellence in the aluminum industry. The company offers a comprehensive range of aluminum products, including profiles, extrusions, and components, to serve the diverse needs of their customers. Their extensive industry experience and technical expertise enable them to deliver solutions that meet the stringent requirements of various applications.[Company Name] has built a strong reputation for providing exceptional customer service and support, with a team of knowledgeable and experienced professionals dedicated to meeting their clients' needs. They work closely with their customers to understand their specific requirements and provide tailored solutions that meet or exceed expectations.The launch of the 1515 Aluminium Profile is a testament to [Company Name]'s ongoing commitment to delivering innovative and high-quality products to the market. With its superior strength, versatility, and durability, this new profile is set to become a preferred choice for a wide range of industrial and construction applications.As a leading player in the aluminum industry, [Company Name] continues to set the benchmark for quality and excellence. Their dedication to continuous improvement and customer satisfaction positions them as a reliable partner for businesses looking for high-quality aluminum solutions. The launch of the 1515 Aluminium Profile is a clear demonstration of their forward-thinking approach and commitment to driving innovation in the industry.In conclusion, the launch of the 1515 Aluminium Profile represents a significant milestone for [Company Name] and underscores their position as a leader in the aluminum industry. With its exceptional features and wide-ranging applications, this new profile is set to make a lasting impact on various sectors. Through their unwavering commitment to excellence, [Company Name] is well-positioned to continue delivering cutting-edge solutions that meet the evolving needs of the industry.

Aluminium Profile for Ender 3 - A Versatile 3D Printer Upgrade

[Company Name], a leading manufacturer of 3D printers and printing accessories, has recently announced the launch of their new Ender 3 Aluminium Profile. This innovative product is set to revolutionize the 3D printing industry with its advanced features and high-quality materials.The Ender 3 Aluminium Profile is a key component of [Company Name]'s Ender 3 series of 3D printers, which are known for their reliability, affordability, and ease of use. The new Aluminium Profile is designed to further enhance the performance and durability of the Ender 3, making it an even more valuable tool for both professional and hobbyist 3D printing enthusiasts.One of the key benefits of the Ender 3 Aluminium Profile is its exceptional strength and stability. Made from high-quality aluminium, this profile provides a sturdy and reliable framework for the 3D printer, ensuring smooth and precise printing results. The use of aluminium also offers excellent heat dissipation, which is crucial for maintaining consistent printing temperatures and achieving high-quality prints.In addition to its robust construction, the Ender 3 Aluminium Profile is designed to be easy to install and compatible with other Ender 3 series components. This allows users to upgrade their existing Ender 3 printers with the new profile, instantly improving their printing experience without the need for a complete overhaul of their equipment."We are thrilled to introduce the Ender 3 Aluminium Profile to the market," said [Company Name]'s CEO. "This new product reflects our commitment to innovation and quality, and we believe it will greatly benefit our customers by enhancing the performance and longevity of their Ender 3 3D printers."The Ender 3 Aluminium Profile is just one example of [Company Name]'s dedication to providing cutting-edge solutions for the 3D printing industry. The company is known for its extensive range of 3D printing products, including printers, filaments, accessories, and upgrades, all of which are designed to meet the diverse needs of 3D printing enthusiasts across the globe.With a strong emphasis on research and development, [Company Name] continues to push the boundaries of 3D printing technology, striving to deliver products that are not only innovative but also practical and user-friendly. This commitment to excellence has earned the company a loyal customer base and a reputation for being a trusted and reliable provider of 3D printing solutions.As the demand for 3D printing continues to grow across various industries, [Company Name] remains at the forefront of the market, consistently introducing new and improved products to meet the evolving needs of its customers. The Ender 3 Aluminium Profile is a prime example of the company's ability to anticipate industry trends and deliver solutions that drive progress and innovation.Customers who are interested in learning more about the Ender 3 Aluminium Profile and other products from [Company Name] can visit the company's website or contact their local authorized distributors. With a solid track record of excellence and a focus on customer satisfaction, [Company Name] is poised to continue making significant contributions to the 3D printing industry and beyond.

Discover the Benefits of 20x40 Aluminum Extrusion for Your Projects

Title: Innovations in Aluminum Extrusion: An Introduction to 20x40 Aluminum ExtrusionIntroduction:In the ever-evolving world of manufacturing and construction, aluminum extrusions have become an integral component due to their versatility, durability, and lightweight properties. Among the various aluminum extrusions available, the 20x40 Aluminum Extrusion (brand name omitted) stands out as an innovative and efficient solution for a myriad of applications. This article aims to explore the remarkable features and applications of the 20x40 Aluminum Extrusion, while also providing an insight into the pioneering company behind its creation.The Advantages of 20x40 Aluminum Extrusion:The 20x40 Aluminum Extrusion offers a host of advantages that have made it a favored choice among architects, engineers, and manufacturers worldwide. Firstly, its lightweight nature combined with exceptional strength makes it ideal for constructing structures that require both durability and ease of installation. Architects and designers appreciate the flexibility it offers in terms of creating aesthetically pleasing shapes and structures.Furthermore, the extrusion process itself allows for immense design freedom, as profiles can be customized to meet specific requirements, including length, cross-section, and even surface finishes. This feature makes 20x40 Aluminum Extrusion highly versatile in various sectors, including construction, automotive, aerospace, and renewable energy.Applications in Construction:In the construction industry, the 20x40 Aluminum Extrusion has emerged as an innovative solution for various applications. Its lightweight property significantly reduces transportation costs and makes on-site handling easier, leading to a more efficient construction process. These extrusions have been widely adopted in the construction of framing systems, partitions, facades, and modular structures due to their strength and adaptability.Additionally, the corrosion resistance of aluminum makes it an ideal choice for applications in coastal areas or regions with harsh weather conditions. Its compatibility with glass allows for the creation of sleek and modern windows and curtain walls.Applications in Automotive and Aerospace Industries:The automotive and aerospace industries have also recognized the benefits of utilizing the 20x40 Aluminum Extrusion. Its lightweight characteristics contribute to fuel efficiency in vehicles, leading to reduced emissions and improved performance. Additionally, the extrusions provide excellent heat dissipation, making them suitable for radiator and cooling components.In aerospace, the need for lightweight materials is paramount, and the 20x40 Aluminum Extrusion demonstrates exceptional strength-to-weight ratio ideal for lightweight airframe structures. Its ability to absorb vibrations and provide stability further enhances its suitability for aircraft components.{"Company Name"}: Driving Aluminum Extrusion InnovationBehind the development and production of the 20x40 Aluminum Extrusion lies the pioneering company, {"Company Name"}. With over two decades of experience in the industry, {"Company Name"} has consistently showcased a commitment to innovation, quality, and customer satisfaction.{"Company Name"}'s state-of-the-art facilities are equipped with advanced extrusion lines, allowing for the precise manufacturing of aluminum profiles in various shapes, sizes, and finishes. The company boasts a team of experienced engineers and technicians who collaborate closely with clients to develop customized solutions tailored to their specific requirements.Moreover, {"Company Name"} places a strong emphasis on sustainability and environmentally conscious practices. The 20x40 Aluminum Extrusion is produced using recycled aluminum, minimizing its environmental impact while maintaining the desired material qualities.Conclusion:The 20x40 Aluminum Extrusion offered by {"Company Name"} showcases the immense potential of aluminum extrusions in today's manufacturing and construction sectors. Its versatility, durability, and lightweight properties make it an ideal choice for a wide range of applications. Whether in construction, automotive, or aerospace industries, the 20x40 Aluminum Extrusion continues to transform the design possibilities and functionalities of various structures.With their ongoing dedication to innovation and quality, {"Company Name"} stands at the forefront of aluminum extrusion technology, driving the industry forward. As demands for efficient and sustainable solutions continue to rise, the 20x40 Aluminum Extrusion is undoubtedly set to play a prominent role in shaping the future of manufacturing and construction.

Aluminum Angle Section: Everything You Need to Know

Aluminium Angle Section: Revolutionizing the Construction IndustryIn the ever-evolving world of construction, innovation and efficiency play a crucial role in ensuring the success of any project. One such advancement that has garnered significant attention is the Aluminium Angle Section, a groundbreaking solution that is revolutionizing the industry. With its exceptional strength, versatility, and durability, this innovative product is rapidly reshaping the way construction professionals approach their work.XXXXX (need remove brand name) is a prominent player in the field, leading the way when it comes to the manufacturing and distribution of Aluminium Angle Sections. The company has firmly established itself as an industry leader, with a commitment to delivering high-quality products that enable builders, architects, and engineers to bring their visions to life.The Aluminium Angle Section manufactured by XXXXX is truly exceptional. It is composed of premium-grade aluminium, ensuring superior strength and durability. This unique material also offers excellent resistance to corrosion, making it an ideal choice for both indoor and outdoor applications. Additionally, its low maintenance requirements and exceptional longevity make it a cost-effective solution for any construction project.One of the key advantages of Aluminium Angle Sections lies in their versatility. These sections come in a wide range of sizes and shapes, allowing builders to cater to the unique needs of each project. Whether it's a small residential renovation or a monumental commercial construction, XXXXX's Aluminium Angle Sections can be easily customized to fit the requirements perfectly. Architects and designers appreciate the freedom this product provides, as it enables them to push the boundaries of creativity.The lightweight nature of Aluminium Angle Section is another standout feature, significantly reducing the workload and costs associated with transportation and installation. Unlike traditional materials such as steel, aluminium is significantly lighter, making it easier to handle without compromising on strength and stability. This feature not only improves efficiency but also contributes to sustainability efforts by reducing the overall carbon footprint of a project.Beyond its intrinsic qualities, XXXXX takes pride in the precision and quality control measures implemented during the manufacturing process. By utilizing state-of-the-art machinery and rigorous testing protocols, the company ensures that every Aluminium Angle Section meets the highest industry standards. This commitment to quality is further bolstered by the company's adherence to international certifications and compliance with safety regulations.Through continuous research and development, XXXXX remains at the forefront of innovation in the aluminium industry. The company invests substantial resources into exploring new manufacturing techniques and materials, constantly pushing the boundaries of what is possible. This unwavering dedication to staying ahead of the curve has allowed XXXXX to build a reputation for excellence within the construction sector.To cater to the diverse needs of their clientele, XXXXX offers comprehensive services that extend beyond the manufacturing and distribution of Aluminium Angle Sections. Their team of experienced professionals provides valuable technical support and guidance throughout the entirety of a project. From the initial design phase to the final installation, XXXXX ensures that their customers receive unparalleled assistance and expertise.In conclusion, the Aluminium Angle Section has emerged as a game-changer in the construction industry. Its unique combination of strength, versatility, and durability has revolutionized the way buildings are designed, constructed, and maintained. Manufacturers like XXXXX continue to lead the way, providing exceptional products and services that enable construction professionals to bring their projects to fruition. With an unwavering commitment to quality and innovation, XXXXX is set to shape the future of the industry for years to come.

Discover the Benefits of Aluminum Extrusion 1515 for Your Next Project

Title: Aluminum Extrusion 1515 - A Game-Changing Solution for Modern IndustriesIntroduction:Aluminum extrusion has emerged as a pioneering solution in various industries, offering unparalleled flexibility and versatility in design. Among the wide array of options available, Aluminum Extrusion 1515 has recently gained significant popularity due to its exceptional properties. This groundbreaking product has opened up new avenues for innovation, revolutionizing industries worldwide.Company Introduction:[Company] is at the forefront of the aluminum extrusion industry, constantly pushing the boundaries of possibility. With a commitment to delivering high-quality products, we strive to meet the evolving needs of diverse industries. Our extensive portfolio includes a wide range of extrusion profiles, each designed to optimize functionality and performance. Over the years, [Company] has gained a stellar reputation for excellence, reliability, and cutting-edge solutions. Our latest offering, Aluminum Extrusion 1515, is a testament to our pursuit of innovation.Aluminum Extrusion 1515:Aluminum Extrusion 1515, developed by [Company], represents a significant advancement in extrusion technology. This profile features a compact square-shaped cross-section, measuring 15mm x 15mm, making it highly suitable for a myriad of applications across industries. Industries such as automotive, aerospace, electronics, machinery, and robotics can benefit immensely from the versatility and adaptability of Aluminum Extrusion 1515.Key Features and Advantages:1. Lightweight and Durable: Aluminum Extrusion 1515 is fabricated using high-quality aluminum alloy, making it lightweight yet exceptionally robust. This property ensures longevity while reducing transportation costs and overall energy consumption.2. Customizable and Modular Design: The unique square profile of Aluminum Extrusion 1515 enables easy customization and modular assembly. This design feature allows for flexible incorporation into various structures, facilitating rapid prototyping and efficient design iterations.3. Enhanced Thermal Performance: Aluminum Extrusion 1515 exhibits excellent heat dissipation properties, making it ideal for applications requiring efficient thermal management. Industries such as electronics and machinery can significantly benefit from the optimized performance levels achieved with this extrusion.4. Compatibility and Versatility: Aluminum Extrusion 1515 seamlessly integrates with an extensive range of accessories, connectors, and fasteners. This compatibility ensures compatibility with other components, enabling greater design options and versatility.5. Streamlined Production Processes: The use of Aluminum Extrusion 1515 simplifies production processes, resulting in cost-effective solutions. Assembly, modification, and disassembly become effortless processes, saving significant time and resources.Applications:1. Automotive Sector: Aluminum Extrusion 1515 finds applications in automotive assemblies, including framework construction, protective barriers, supports, and safety systems. The lightweight nature of the extrusion reduces vehicle weight, enhancing fuel efficiency and overall performance.2. Aerospace Industry: The aerospace sector extensively employs Aluminum Extrusion 1515 due to its lightweight properties and exceptional strength-to-weight ratio. It is used in the manufacturing of aircraft frames, internal structures, cabin components, and cargo systems.3. Electronics and Automation: The compact design and enhanced thermal performance of Aluminum Extrusion 1515 make it an ideal choice for electronics housing, printed circuit board (PCB) support, and automation systems. Its modular design simplifies integration with electronic components, ensuring efficient heat dissipation.Conclusion:Aluminum Extrusion 1515, developed by [Company], represents a breakthrough in the aluminum extrusion industry. Its unique properties, including lightweight construction, modular design, and excellent thermal performance, have positioned it as a game-changing solution for various industries. As demand for innovative and sustainable solutions grows, Aluminum Extrusion 1515 continues to revolutionize modern manufacturing, offering limitless possibilities across sectors worldwide.

Understanding the Process and Benefits of Extruded Aluminum

The 1515 Extruded Aluminum has become a popular choice among manufacturers and fabricators due to its versatility and durability. With its high strength-to-weight ratio and corrosion resistance, it is an ideal material for a wide range of applications, including construction, automotive, aerospace, and industrial machinery.The 1515 Extruded Aluminum is manufactured by a leading company in the industry, which has been providing high-quality aluminum products for decades. With state-of-the-art manufacturing facilities and a team of skilled engineers and technicians, the company is committed to producing top-notch aluminum extrusions that meet the highest industry standards.One of the key features of the 1515 Extruded Aluminum is its versatility. It can be easily machined, welded, and formed into complex shapes, making it suitable for a wide range of applications. Whether it is used for structural components, heat exchangers, or decorative architectural elements, the 1515 Extruded Aluminum offers unmatched flexibility and precision.In addition, the 1515 Extruded Aluminum boasts exceptional corrosion resistance, making it an ideal choice for outdoor and marine applications. Its ability to withstand harsh environmental conditions and exposure to chemicals and saltwater makes it a popular choice for a variety of outdoor and marine applications.Furthermore, the 1515 Extruded Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for lightweight yet strong structures. This makes it a popular choice for manufacturers and fabricators looking to reduce weight and improve fuel efficiency in their products.The 1515 Extruded Aluminum is also an eco-friendly choice, as it is fully recyclable and can be reused in a wide range of applications. This sustainable aspect of the material makes it a popular choice for companies looking to reduce their environmental impact and meet green building standards.The company behind the 1515 Extruded Aluminum is dedicated to providing exceptional customer service and support. With a team of knowledgeable sales representatives and technical experts, they are committed to helping their customers find the right aluminum solutions for their specific needs. Whether it is providing technical guidance, design assistance, or custom extrusion services, the company is known for its commitment to customer satisfaction.Moreover, the company is continuously investing in research and development to enhance the performance and versatility of their aluminum products. This commitment to innovation and continuous improvement ensures that their customers have access to the latest advancements in aluminum technology.In conclusion, the 1515 Extruded Aluminum is a versatile and durable material that is widely used in a variety of industries. With its high strength-to-weight ratio, corrosion resistance, and eco-friendly properties, it is an ideal choice for manufacturers and fabricators looking for a reliable and sustainable aluminum solution. Backed by a reputable company with a commitment to quality and customer satisfaction, the 1515 Extruded Aluminum continues to be a top choice for a wide range of applications.

Durable and Lightweight Aluminum Top Hat Extrusion for Various Applications

【Introduction】In a recent development in the field of aluminum extrusion technology, a cutting-edge solution known as Aluminum Top Hat Extrusion has emerged, revolutionizing industries that rely on lightweight, durable, and versatile materials. Conceived and developed by a pioneering company specializing in aluminum extrusions, this innovative product offers an array of benefits for various applications in different sectors. By removing the brand name from the news, we can focus on the essence of this groundbreaking invention and showcase its potential impact on the industry.【Body】Aluminum Top Hat Extrusion is an advanced manufacturing technique that involves shaping aluminum into a distinctive profile resembling a top hat. This unique design allows for exceptional structural strength while minimizing weight. The extrusion process involves shaping heated aluminum alloy billets using specialized dies to create the desired profile. Through precise control of temperature, pressure, and extrusion speed, the finely crafted top hat profile is produced with impeccable precision.The design of the Aluminum Top Hat Extrusion is highly flexible and customizable, making it suitable for a wide range of applications across industries. Whether it is for automotive components, aerospace structures, architectural elements, or electrical enclosures, this extrusion profile offers a vast array of possibilities. Its lightweight nature and superior strength-to-weight ratio make it an ideal choice for applications requiring both durability and efficient use of resources.One of the key advantages of Aluminum Top Hat Extrusion lies in its exceptional thermal and electrical conductivity. Aluminum is widely recognized for its excellent heat dissipation properties, enabling it to regulate temperatures efficiently. This makes the extruded top hat profile particularly desirable for applications where thermal management is critical, such as heat sinks for electronic devices or cooling systems for engines.Furthermore, the electrical conductivity of aluminum enhances its appeal in industries that require effective grounding or the transmission of electrical currents. The top hat extrusion profile can be integrated into electrical enclosures, power distribution systems, or wiring channels, ensuring optimal electrical performance and safety.In addition to its functional advantages, the Aluminum Top Hat Extrusion boasts an appealing aesthetic appeal. Its sleek, modern design enhances the visual appeal of various products and architectural structures, making it a popular choice among designers and architects. Moreover, the extruded profile can be anodized or coated with different finishes, adding an extra layer of durability and corrosion resistance.Considering the broader environmental implications, Aluminum Top Hat Extrusion aligns with the growing demand for sustainable materials and manufacturing processes. Aluminum is highly recyclable, and its extrusion enables the creation of complex shapes without sacrificing material integrity. This reduces waste and contributes to a more circular economy.The introduction of Aluminum Top Hat Extrusion represents a significant leap forward in aluminum extrusion technology. The groundbreaking design, combined with its exceptional strength, lightweight composition, and versatile applications, positions it as a viable alternative to traditional manufacturing solutions. It opens up new possibilities for industries aiming to enhance performance, reduce weight, and improve the overall efficiency of their products.As diverse sectors continually seek innovative solutions to remain competitive in an ever-evolving market, the Aluminum Top Hat Extrusion offers an exciting opportunity to revolutionize processes, increase sustainability, and redefine industry standards. With its broad range of applications and unparalleled performance, this aluminum extrusion profile is poised to shape the future of numerous industries.【Conclusion】The Aluminum Top Hat Extrusion represents a significant breakthrough in aluminum extrusion technology. Its unique design, exceptional strength, lightweight composition, and versatile applications position it as a game-changer across multiple sectors. From automotive and aerospace to architecture and electronics, this revolutionary extrusion profile offers a wide range of benefits, including enhanced durability, superior thermal and electrical conductivity, and aesthetic appeal. As industries strive for innovation and sustainability, the Aluminum Top Hat Extrusion provides an exciting opportunity to reshape manufacturing processes and elevate product performance to new heights.

Powerful Aluminium Extrusions - Discover the Benefits of 20x20 Dimensions!

Aluminium 20x20: Revolutionizing the Metal IndustryThe metal industry has always played a significant role in numerous sectors, from construction to aerospace. One of the most versatile and commonly used metals is aluminium. Known for its lightweight and corrosion-resistant properties, aluminium has become a staple in manufacturing processes worldwide. In recent years, a new development has taken the industry by storm - Aluminium 20x20, an innovative product set to revolutionize metal applications.[Company name], a leader in the metal manufacturing space, has introduced Aluminium 20x20, a groundbreaking advancement in aluminium composition. This particular product boasts exceptional strength and durability, taking aluminium's characteristics to an entirely new level. With the incorporation of unique alloying elements, Aluminium 20x20 offers enhanced mechanical performance, providing significant benefits in a wide range of applications.The key distinguishing feature of Aluminium 20x20 lies in its immense strength-to-weight ratio. In comparison to standard aluminium alloys, this new composition offers a weight reduction of 20% without compromising integrity or performance. This game-changing characteristic has made Aluminium 20x20 highly sought-after across industries, as it allows for increased efficiency and lower operational costs. Additionally, its improved strength makes it a prime choice for applications requiring heightened load-bearing capabilities.The application possibilities for Aluminium 20x20 are virtually limitless. In architecture and construction, this revolutionary product can be utilized for structural elements, such as beams and columns, offering superior strength while reducing material and labor costs. The transportation sector can benefit from Aluminium 20x20's lightweight nature, enabling lighter and more fuel-efficient vehicles. Moreover, its exceptional corrosion resistance makes it an ideal choice for marine applications, where exposure to water and salt can deteriorate traditional metals quickly.When it comes to aerospace, Aluminium 20x20 has the potential to transform the industry. Aircraft manufacturers and designers can leverage its high strength-to-weight ratio, resulting in increased payload capacities and reduced fuel consumption, which translates into substantial operational savings. Additionally, its resistance to fatigue makes Aluminium 20x20 an attractive option for aircraft components that endure repeated stress from takeoffs and landings.Beyond its mechanical properties, Aluminium 20x20 aligns closely with the growing emphasis on sustainability. The manufacturing of this innovative metal involves fewer resources and less energy compared to traditional alloys, making it environmentally friendly. Additionally, as the product requires less material due to its increased strength, the overall carbon footprint is significantly reduced.[Company name], with its extensive experience in the metal industry, has been at the forefront of Aluminium 20x20's development and production. By leveraging cutting-edge manufacturing techniques and state-of-the-art facilities, the company ensures consistent quality and performance in every batch of Aluminium 20x20 produced. The company's commitment to research and development has enabled them to remain a trusted name in the industry, consistently pushing boundaries and introducing innovative solutions.The introduction of Aluminium 20x20 marks a new era in the metal industry. Its exceptional strength, reduced weight, and sustainability make it a game-changer in various sectors. With its widespread applications, from construction to aerospace, Aluminium 20x20 is poised to reshape industries, increasing efficiency and paving the way for a more sustainable future. As [Company name] continues to innovate, it is evident that Aluminium 20x20's influence will extend far beyond present expectations, driving progress and efficiency in diverse industries globally.