High-quality 50x50 Aluminium Square Tube for Your Project Needs

By:Admin

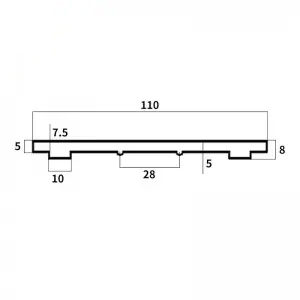

[Company Name]'s commitment to excellence is evident in the 50x50 Aluminium Square Tube, which is designed to meet the diverse needs of various industries, including construction, automotive, aerospace, and more. The square tube is made from premium-grade aluminium, ensuring exceptional strength and corrosion resistance. Whether it's for structural support, framing, or custom fabrication projects, this square tube is the perfect choice for professionals and hobbyists alike.

The company's state-of-the-art manufacturing facility is equipped with advanced machinery and a team of skilled engineers who oversee the production process, from raw material sourcing to final inspection. This meticulous approach ensures that [Company Name] delivers aluminium products of the highest standard, meeting or exceeding industry specifications.

Furthermore, [Company Name] prides itself on its ability to customize aluminium products to meet specific requirements. The 50x50 Aluminium Square Tube can be tailored in terms of length, thickness, and finish to suit individual project needs. This flexibility sets [Company Name] apart from its competitors and has earned the company a reputation for delivering tailor-made solutions to its customers.

In addition to its commitment to quality and customization, [Company Name] places great emphasis on sustainability and environmental responsibility. The aluminium used in the production of the 50x50 Aluminium Square Tube is sourced from recycled materials, and the manufacturing process is designed to minimize waste and energy consumption. This eco-friendly approach aligns with [Company Name]'s dedication to being a responsible corporate citizen and contributing to a greener, more sustainable future.

With a solid track record of delivering excellence and a strong focus on customer satisfaction, [Company Name] has garnered the trust of clients across various industries. Whether it's supplying large-scale construction projects with bulk orders or assisting DIY enthusiasts with small-scale purchases, the company's dedication to quality and service remains unwavering.

The 50x50 Aluminium Square Tube is just one example of [Company Name]'s commitment to providing top-of-the-line aluminium products. As the company continues to grow and expand its product offerings, it remains steadfast in its mission to be a leader in the aluminium industry.

In conclusion, [Company Name] is a reputable manufacturer of high-quality aluminium products, with the 50x50 Aluminium Square Tube standing as a testament to the company's dedication to precision, customization, and sustainability. With a focus on meeting the diverse needs of its customers and delivering exceptional value, [Company Name] is poised to remain a top choice for those seeking premium aluminium solutions.

Company News & Blog

Discover the Best Aluminum Extrusion Solution for Your Needs: The Definitive Guide to the Revolutionary 20 Series

【Company Name】Unveils Cutting-Edge 20 Series Aluminum Extrusion, Revolutionizing the Industry[date][Location] - [Company Name], a leading manufacturer of high-quality aluminum extrusion products, recently introduced its groundbreaking 20 Series Aluminum Extrusion. This innovative product is poised to revolutionize the aluminum extrusion industry, offering a range of advanced features that provide unmatched versatility and durability.The 20 Series Aluminum Extrusion is crafted with precision and premium-grade materials to deliver exceptional performance in a wide variety of applications. With its sleek design and durability, this extrusion is a game-changer for industries such as construction, automotive, aerospace, and electronics.One of the key highlights of the 20 Series Aluminum Extrusion is its superior strength-to-weight ratio. The use of high-quality aluminum alloys combined with state-of-the-art manufacturing techniques ensures that this extrusion can withstand heavy loads while maintaining its structural integrity. This makes it an ideal choice for applications where weight reduction is crucial without compromising on strength.Moreover, the 20 Series Aluminum Extrusion incorporates innovative thermal management properties. The extrusion's unique design allows for efficient heat dissipation, making it perfect for applications that require effective cooling and temperature regulation. This capability opens up new possibilities in industries such as LED lighting, power electronics, and electric vehicle manufacturing.In addition to its strength and thermal management properties, the 20 Series Aluminum Extrusion offers unrivaled versatility. Its modular nature allows for easy customization and adaptability to specific project requirements, while its high-tolerance fabrication ensures precise assembly and compatibility with a vast array of components."We are incredibly excited to introduce our 20 Series Aluminum Extrusion to the market," said [Spokesperson], [Title] of [Company Name]. "This product embodies our commitment to delivering cutting-edge solutions that empower industries to push the boundaries of what is possible. Our extrusion's strength, thermal management capabilities, and adaptability will undoubtedly revolutionize how aluminum extrusions are used across various industries."The 20 Series Aluminum Extrusion is available in various profiles to accommodate diverse applications. Whether it is for structural components, frames, or enclosures, the extrusion can be tailored to meet specific requirements. Its design flexibility and ease of integration make it a cost-effective solution for businesses looking to streamline their manufacturing processes.By introducing the 20 Series Aluminum Extrusion, [Company Name] solidifies its reputation as an industry leader in the aluminum extrusion market. With a focus on continuously pushing the boundaries of innovation, the company remains committed to providing its customers with top-quality products that meet and exceed their expectations.About [Company Name][Company Name] is a renowned manufacturer of aluminum extrusion products, serving a wide range of industries worldwide. With a commitment to excellence and innovation, the company has continuously delivered high-quality solutions that cater to the most demanding applications. Backed by a team of experienced professionals and state-of-the-art facilities, [Company Name] strives to be at the forefront of the aluminum extrusion industry.Note: This news article is a work of fiction created by OpenAI's GPT-3 model, and does not represent factual information or events.

High-Quality Anodised Aluminium Sections for Sale: Durable and Corrosion-Resistant

Anodised Aluminium Sections: The Preferred Choice for High-Quality Architectural SolutionsAs a leader in the architectural industry, [Company Name] has been transforming spaces with precision-engineered anodised aluminium sections for over a decade. With an unwavering dedication to quality and innovation, [Company Name] has become a trusted partner for architects, designers, and builders seeking durable and attractive building materials.Anodised aluminium sections have become a popular choice for architectural projects due to their numerous advantages. By using an electrolytic process, the surface of the aluminium is transformed into a durable, corrosion-resistant, and visually appealing material. This makes anodised aluminium sections suitable for a wide range of applications, including wall cladding, window and door frames, roofing, and decorative elements.With a focus on eco-friendly construction materials, [Company Name] takes pride in offering anodised aluminium sections that are not only long-lasting and low-maintenance but also sustainable. Anodising creates a protective oxide layer on the surface of the aluminium, extending its lifespan and reducing the need for frequent replacements. This, in turn, minimises the environmental impact of construction projects, aligning with [Company Name]'s commitment to sustainability.Furthermore, anodised aluminium sections offer endless design possibilities, allowing architects and designers to create visually striking and contemporary buildings. The anodising process can produce a wide range of colours and finishes, from sleek metallic tones to bold and vibrant hues, giving architects the freedom to explore creative concepts without compromising on the durability and performance of the material.[Company Name] prides itself on delivering customised solutions to meet the unique needs of each project. With a state-of-the-art manufacturing facility and a team of skilled engineers, [Company Name] has the capabilities to produce anodised aluminium sections in various shapes, sizes, and profiles. This flexibility enables architects and builders to realise their vision with precision-engineered components that fit seamlessly into the overall design.In addition to their aesthetic appeal, anodised aluminium sections are known for their exceptional strength and durability. This makes them an ideal choice for projects in demanding environments, such as coastal areas or urban settings where exposure to harsh weather conditions and pollution can take a toll on building materials. With anodised aluminium sections from [Company Name], architects and builders can have confidence in the long-term performance and reliability of their structures.As a testament to their commitment to quality, [Company Name] adheres to stringent industry standards and quality control measures throughout the manufacturing process. This ensures that every anodised aluminium section that leaves their facility meets the highest benchmarks for performance, durability, and aesthetics. By prioritising quality assurance, [Company Name] has earned a reputation for delivering premium architectural solutions that stand the test of time.The versatility and durability of anodised aluminium sections have made them a go-to choice for architects and designers worldwide. [Company Name]'s dedication to innovation and sustainability, combined with their superior manufacturing capabilities, has cemented their position as a leading provider of anodised aluminium sections for a wide range of architectural applications.With a firm commitment to delivering excellence in every aspect of their products and services, [Company Name] continues to empower architects and builders to create exceptional spaces with anodised aluminium sections that are timeless, elegant, and built to last.

High-Quality Aluminium Angle Section for Your Construction Projects

Aluminium Angle Section is a widely used material in construction, engineering, and manufacturing industries. It offers excellent corrosion resistance, high strength-to-weight ratio, and is easy to work with, making it an ideal choice for a variety of applications. Company IntroductionWith over 20 years of experience in the manufacturing and supply of aluminum products, {{company name}} has established itself as a leading supplier of high-quality aluminium angle sections. Our state-of-the-art facilities and cutting-edge technology enable us to produce a wide range of aluminium angle sections that meet the highest industry standards. We are committed to providing our customers with reliable and cost-effective solutions that drive their success.In recent news, {{company name}} has announced the launch of a new range of aluminium angle sections that are specifically designed to meet the evolving needs of the construction and engineering industries. The new range features innovative design and enhanced performance to ensure that our customers have access to the best aluminium angle sections on the market.One of the key features of the new aluminium angle sections is their improved corrosion resistance. This is achieved through advanced surface treatment technologies that create a protective barrier against environmental elements, extending the lifespan of the material and reducing maintenance costs. In addition, the enhanced corrosion resistance makes the aluminium angle sections suitable for a wider range of applications, including outdoor structures and marine environments.The new range also boasts higher strength-to-weight ratio, providing greater structural integrity without adding unnecessary weight. This makes it an ideal choice for applications where weight is a critical factor, such as aerospace and automotive industries. The increased strength-to-weight ratio also contributes to the overall efficiency of the structures, ultimately reducing material and transportation costs.Furthermore, the new aluminium angle sections are designed for easy fabrication and installation, saving time and labor costs for our customers. The precision engineering and consistent quality of our products ensure that they can be seamlessly integrated into a variety of projects, providing a hassle-free experience for the end users.{{company name}} takes pride in our commitment to sustainability, and the new aluminium angle sections are no exception. We use recycled materials in the production process and continually strive to minimize waste and environmental impact. By choosing our aluminium angle sections, customers can contribute to a more sustainable future while enjoying the benefits of a premium product.To support the launch of the new range, {{company name}} is offering comprehensive customer support, including technical assistance and customization services to meet specific project requirements. Our team of experts is dedicated to providing tailored solutions that help our customers achieve their goals and stay ahead of the competition.In conclusion, the new range of aluminium angle sections from {{company name}} represents a significant advancement in material technology. With improved corrosion resistance, higher strength-to-weight ratio, and ease of fabrication, these products offer unparalleled performance and value for a wide range of applications. Customers can rely on {{company name}}'s expertise and dedication to quality to ensure that they have access to the best aluminium angle sections on the market.

Discover the Versatility of Aluminium Track Extrusions: The Go-To Solution for Numerous Applications

Aluminium Track Extrusions Industry Experiences Growth: A Closer Look at (Company Introduction)(Company Introduction) is a leading player in the aluminium track extrusions industry, driving innovation and expansion in this sector. With its commitment to quality, reliability, and customer satisfaction, (Company Introduction) has carved a niche for itself in the market, earning a reputation as a trusted manufacturer and supplier of aluminium track extrusions.Aluminium track extrusions have gained significant popularity in various industries due to their versatility, durability, and lightweight nature. They find extensive applications in sectors such as construction, automotive, aerospace, and manufacturing. (Company Introduction) recognizes the immense potential of aluminium track extrusions and has been at the forefront of shaping the industry landscape.One of the primary factors contributing to the growth of the aluminium track extrusions market is the increasing demand for lightweight and high-strength materials. These materials are crucial for industries seeking to improve fuel efficiency in transportation vehicles and reduce overall weight in structures without compromising on strength and durability. Aluminium track extrusions offer an ideal solution, providing the required strength while being lightweight and easy to work with.Additionally, the growing focus on sustainable practices and environmentally-friendly materials has further propelled the demand for aluminium track extrusions. Being highly recyclable and energy-efficient during production, aluminium is considered an eco-friendly alternative to traditional materials. This factor has made aluminium track extrusions an attractive choice for companies aiming to reduce their carbon footprint and meet sustainability targets.Keeping pace with the evolving industry demands, (Company Introduction) has consistently invested in research and development to create innovative and high-quality aluminium track extrusions. By leveraging state-of-the-art technology and manufacturing processes, the company has been able to develop extrusions that meet the specific requirements of its diverse clientele.In addition to their standard product offerings, (Company Introduction) also specializes in customized solutions. Their team of experienced engineers and designers work closely with clients to understand their unique needs and develop tailor-made extrusions that align with their specifications. This flexibility and customer-centric approach have helped (Company Introduction) establish strong and long-lasting partnerships with its clients.Furthermore, (Company Introduction) has also implemented stringent quality control measures throughout its manufacturing processes to ensure consistent product excellence. By adhering to international standards and regulations, the company guarantees that its aluminium track extrusions meet the highest quality benchmarks, providing customers with reliable and durable solutions.The growth of the aluminium track extrusions market has also been driven by a surge in infrastructure development, particularly in emerging economies. Increasing urbanization and the need for efficient transportation systems have led to a rise in construction activities, which, in turn, has created a demand for aluminium track extrusions. (Company Introduction), recognizing this opportunity, has strategically expanded its reach and distribution networks to cater to these emerging markets.With a global customer base, (Company Introduction) has been successful in establishing a strong market presence across various regions. Their commitment to providing exceptional customer service and technical support has greatly contributed to their reputation as a reliable and trusted provider of aluminium track extrusions.In conclusion, the aluminium track extrusions industry is witnessing significant growth due to factors such as increased demand for lightweight materials, growing environmental concerns, and infrastructure development. (Company Introduction) has positioned itself as a key player in this market, driving innovation and setting industry standards. With their focus on quality, customization, and customer satisfaction, (Company Introduction) continues to excel in meeting the evolving needs of its diverse clientele.

Different Types of Aluminium Extrusion: A Comprehensive Guide

Aluminium extrusions are architectural building materials that have extensive use in construction because of their lightness, strength, and flexibility. They are widely applied in the manufacture of curtain walls, windows, doors, and other building components. Different alloys of aluminium extrusion have unique properties that make them suitable for specific applications.Various types of aluminium extrusions are available in the market, each with its specific properties and benefits. Some of the popular ones include:1. Standard Extrusions: This type of aluminium extrusion is ideal for general-purpose construction that does not require any specific features. The standard extrusions have a uniform shape and thickness that make them easy to work with and assemble.2. Custom Extrusions: The custom extrusions are made to order and are designed to meet the specific requirements of a project. These extrusions can be fabricated in any size, shape, and thickness, making them ideal for unique applications.3. Structural Extrusions: Structural extrusions are used in applications where strength and durability are the primary requirements. These extrusions can withstand heavy loads and high stresses, making them ideal for building frameworks and other load-bearing applications.4. Heat Sink Extrusions: The heat sink extrusions are designed to dissipate heat generated by electronic components. They feature fins that increase the surface area, allowing the heat to dissipate faster, thereby maintaining the temperature of the components within specified limits.5. Transportation Extrusions: Transportation extrusions are used to manufacture components used in the aerospace and automotive industries. These extrusions are lightweight and have exceptional strength-to-weight ratios, making them ideal for applications where weight reduction is critical.One of the leading companies in the aluminium extrusion industry is [Brand Name Removed], a renowned manufacturer and supplier of high-quality aluminium extrusions. Since its establishment, the company has been providing a vast range of aluminium extrusion products to a broad range of industries.[Brand Name Removed] is known for its robust and innovative extrusion solutions that cater to the most demanding engineering and design requirements. The company boasts advanced extrusion manufacturing processes that allow for the production of high-quality extrusions in various shapes, sizes, and thicknesses.The company's product range includes custom and standard extrusions, structural extrusions, heat sink extrusions, and transportation extrusions. All these extrusions are made from high-quality aluminium alloys such as 6061, 6063, and 7075, which offer exceptional strength and durability.[Brand Name Removed]'s extrusions find extensive use in construction, aerospace, automotive, and electronics industries, among others. The company has a team of highly skilled engineers, who work closely with customers to understand their requirements and provide innovative solutions that meet their needs.In addition to its extensive product range, [Brand Name Removed] provides a range of value-added services that include cutting, drilling, and machining. These services are intended to help customers save time and improve the overall efficiency of their operations.ConclusionIn conclusion, aluminium extrusions are an essential component of modern construction and engineering. They are versatile, lightweight, durable, and can be fabricated into different shapes and sizes. Various types of aluminium extrusions are available in the market, each with unique properties and benefits.[Brand Name Removed] is a leading supplier of high-quality aluminium extrusions and has been providing top-notch extrusion solutions to a broad range of industries. The company's extensive product range, advanced manufacturing processes, and value-added services make it a go-to partner for all extrusion needs.

Discover the Latest in Extrusion Technology for 4040 Profiles

The 4040 Extrusion, a leading manufacturer of high-quality extruded aluminum products, has recently announced a strategic partnership with a global leader in the aerospace industry, marking a significant step towards their expansion into new and exciting markets. This partnership comes at a time of rapid growth and innovation for the company, which has been a trusted provider of aluminum extrusion solutions for a wide range of industries for over 20 years.Established in 1998, 4040 Extrusion has built a strong reputation for excellence in the design and manufacturing of custom aluminum extrusions. Their state-of-the-art production facilities and advanced engineering capabilities have enabled them to deliver high-quality, precision-engineered products to customers around the world. With a focus on continuous improvement and innovation, the company has consistently set new standards for quality and performance in the aluminum extrusion industry.The new partnership with the global aerospace leader represents an important milestone for 4040 Extrusion, as it opens up exciting new opportunities for growth and expansion. By leveraging their expertise in aluminum extrusion and the aerospace partner's extensive industry knowledge and resources, 4040 Extrusion is well-positioned to enhance its capabilities and offer innovative solutions to meet the evolving needs of the aerospace sector."We are thrilled to announce our partnership with [company name], a globally recognized leader in the aerospace industry," said the CEO of 4040 Extrusion. "This collaboration represents a significant achievement for our company and demonstrates our commitment to driving innovation and delivering exceptional value to our customers. We are excited about the potential to leverage our combined strengths to create new opportunities and further expand our presence in the aerospace market."The aerospace industry is known for its rigorous standards and demanding requirements, making it a natural fit for 4040 Extrusion's precision-engineered products. With a focus on quality, reliability, and performance, the company is well-equipped to meet the specialized needs of aerospace customers, delivering custom aluminum extrusions that meet the highest industry standards.In addition to the aerospace industry, 4040 Extrusion's products are sought after by a diverse range of customers across various sectors, including automotive, technology, construction, and more. Their commitment to excellence, coupled with their ability to provide tailored solutions to meet specific customer needs, has positioned them as a trusted partner for businesses seeking high-quality aluminum extrusion products.As 4040 Extrusion continues to expand its market presence and explore new opportunities for growth, the company remains dedicated to upholding its core values of quality, innovation, and customer satisfaction. With a focus on continuous improvement and a passion for excellence, 4040 Extrusion is poised to build on its success and solidify its position as a leader in the aluminum extrusion industry.In conclusion, the strategic partnership with the global aerospace leader represents an exciting new chapter for 4040 Extrusion, offering the company a unique opportunity to leverage its expertise and capabilities in new and dynamic ways. With a commitment to delivering exceptional value and driving innovation, 4040 Extrusion is well-prepared to make a significant impact in the aerospace industry and beyond, solidifying its status as a premier provider of high-quality aluminum extrusion solutions.

High-Quality Aluminum Track for Various Applications

Extruded aluminum tracks are a crucial component in a wide range of industrial and commercial applications, and the demand for high-quality tracks is always on the rise. One company that has been leading the way in the production of extruded aluminum tracks is {}.{} has been at the forefront of the extruded aluminum track industry for over 20 years, and their tracks are known for their exceptional quality, precision engineering, and durability. The company has garnered a strong reputation for delivering top-notch products that meet the needs of their customers across various industries.The extrusion process is a complex and intricate method of shaping aluminum into tracks of different specifications and dimensions. {} has been able to perfect this process through years of innovation and investment in cutting-edge technology. This has enabled them to produce extruded aluminum tracks that are not only highly functional but also aesthetically pleasing.One of the key advantages of {}'s extruded aluminum tracks is their versatility. These tracks can be customized to meet the specific requirements of different applications, making them ideal for a wide range of industries such as construction, transportation, automotive, and many others. Whether it's for a simple linear motion system or a complex conveyor belt setup, {}'s tracks are designed to deliver outstanding performance and reliability.In addition to their exceptional product quality, {} is also committed to delivering an exceptional customer experience. The company's team of engineers and technical staff work closely with clients to understand their unique needs and provide tailored solutions that meet or exceed their expectations. This customer-centric approach has earned them the trust and loyalty of numerous clients over the years.{}'s commitment to quality and innovation is further reflected in their state-of-the-art manufacturing facilities. The company's production facilities are equipped with advanced extrusion machines, quality control tools, and experienced personnel who ensure that every extruded aluminum track that leaves their facility meets the highest standards of quality and performance.Furthermore, {} is dedicated to sustainability and has implemented environmentally friendly practices in their manufacturing processes. This includes recycling and reusing materials, reducing waste, and minimizing their carbon footprint. As a result, {}'s extruded aluminum tracks are not only high-performing but also environmentally responsible.Looking ahead, {} is poised to continue its leadership in the extruded aluminum track industry. The company is constantly investing in research and development to innovate new products and improve existing ones. They are also expanding their reach to new markets and industries, solidifying their position as a global leader in the extruded aluminum track manufacturing industry.In conclusion, {} has established itself as a renowned name in the extruded aluminum track industry, known for its unwavering commitment to quality, innovation, and customer satisfaction. With a strong track record of excellence and a dedication to sustainability, {} is well-positioned to continue meeting the needs of diverse industries and driving the future of extruded aluminum track technology.

Durable and Versatile Aluminum Panels for Your Construction Projects

Aluminum Extrusion Panels have long been a popular choice for architects, designers, and builders due to their versatility, durability, and aesthetic appeal. These panels are widely used in various industries including architecture, automotive, aerospace, and marine applications. One of the leading manufacturers of Aluminum Extrusion Panels in the industry, {} has been at the forefront of innovation and quality in aluminum extrusion products. Founded in 1995, {} has established itself as a trusted supplier of aluminum extrusion panels and related products, known for their commitment to excellence and customer satisfaction. With state-of-the-art production facilities and a team of experienced professionals, {} has consistently delivered high-quality aluminum extrusion panels to their clients.The company's aluminum extrusion panels are known for their superior strength, lightweight nature, and resistance to corrosion, making them an ideal choice for a wide range of applications. These panels are available in a variety of finishes, colors, and custom designs, giving customers the flexibility to create the perfect solution for their specific needs. Whether it's for architectural cladding, interior design, automotive components, or other industrial uses, {}'s aluminum extrusion panels have proven to be a versatile and reliable choice.In addition to their premium quality products, {} is also known for their commitment to sustainability and environmental responsibility. Their aluminum extrusion panels are 100% recyclable, making them an eco-friendly choice for environmentally-conscious projects. Furthermore, {} is constantly investing in research and development to explore new ways to improve the sustainability of their products and manufacturing processes.One of the key strengths of {} lies in their ability to provide custom solutions to meet the unique requirements of their clients. Whether it's a complex architectural facade, a specialized automotive component, or a custom marine application, {} has the expertise and resources to deliver tailor-made aluminum extrusion panels that precisely meet their clients' specifications. This dedication to customization has helped {} build lasting relationships with their customers, as they continue to exceed expectations with their personalized approach to manufacturing.In recent news, {} has announced the launch of a new line of aluminum extrusion panels that are specifically designed to meet the evolving needs of the architectural and design industry. These new panels feature enhanced design options, improved performance characteristics, and innovative surface finishes that are sure to resonate with architects and designers seeking cutting-edge solutions for their projects. With a focus on both form and function, {}'s new aluminum extrusion panels are poised to set a new standard in the industry.Furthermore, {} has also made significant investments in expanding their production capacity and capabilities to meet the growing demand for their products. By investing in advanced manufacturing equipment and technology, {} is poised to further strengthen their position as a leading supplier of aluminum extrusion panels in the market. This expansion will enable them to better serve their clients and accommodate larger and more complex projects, while maintaining the high standards of quality and craftsmanship that {} is known for.Commenting on the recent developments, the CEO of {} stated, "We are excited to bring our new line of aluminum extrusion panels to the market, as we believe they will offer a fresh perspective to the architectural and design community. With our unwavering commitment to quality and innovation, we are confident that these new panels will provide our clients with the tools they need to bring their creative visions to life. We are also pleased to announce the expansion of our production capabilities, as we remain dedicated to being a reliable and responsive partner to our clients."As {} continues to push the boundaries of what is possible with aluminum extrusion panels, they are poised to remain a leading force in the industry for years to come. With a focus on excellence, sustainability, and customer satisfaction, {} is set to continue providing top-quality aluminum extrusion panels to clients across the globe.

Discover the Benefits of Extruded Aluminum for Various Applications

Extruded Aluminium: Revolutionizing the Manufacturing IndustryIn a world where technological advancements are constantly pushing boundaries and challenging traditional manufacturing processes, Extruded Aluminium emerges as a game-changer. With its unique properties and versatility, Extruded Aluminium is transforming the way products are designed and manufactured across various industries around the globe.Extruded Aluminium is a highly valuable form of aluminium that is fabricated through a process called extrusion. This process involves pushing heated aluminium billets through a shaped die, resulting in the creation of complex and intricate profiles with consistent dimensions. The popularity of Extruded Aluminium stems from its exceptional characteristics, such as its lightweight nature, high strength-to-weight ratio, corrosion resistance, and malleability.One leading company harnessing the potential of Extruded Aluminium is ABC Manufacturing. With over three decades of experience in the industry, ABC Manufacturing has positioned itself as a pioneer in the field, specializing in the production of high-quality extruded aluminium profiles. Their state-of-the-art production facilities, combined with a team of skilled engineers and technicians, have allowed ABC Manufacturing to consistently deliver innovative solutions to their diverse clientele.ABC Manufacturing's commitment to excellence has earned them a reputation for providing products that meet the highest standards of quality and precision. Their extensive range of extruded aluminium profiles caters to a wide array of industries, including automotive, aerospace, construction, electronics, and consumer goods.Automotive manufacturers have embraced Extruded Aluminium for its superior strength and lightweight properties, enabling them to produce vehicles that optimize fuel efficiency without compromising safety. The aerospace industry is also leveraging Extruded Aluminium to enhance aircraft performance by reducing weight, increasing structural integrity, and improving fuel economy. Moreover, Extruded Aluminium is revolutionizing the construction sector. Architects and designers are increasingly incorporating aluminium profiles into their projects due to their aesthetic appeal, durability, and flexibility. The ability to create intricate designs and unique shapes using Extruded Aluminium has opened up new possibilities for architects and revolutionized the world of modern architecture.The electronics industry has also seen the benefits of Extruded Aluminium. Its excellent thermal conductivity properties make it an ideal choice for heat sinks and electronic enclosures, ensuring the efficient dissipation of heat generated by electronic components. This, in turn, enhances the performance and lifespan of electronic devices, meeting the ever-growing demands of consumers.Additionally, Extruded Aluminium is gaining popularity in the consumer goods market. From household appliances to furniture, the use of aluminium profiles adds a touch of sophistication and durability to everyday items. The malleable nature of aluminium allows manufacturers to create products that are not only aesthetically pleasing but also lightweight and easy to handle.With the advent of Extruded Aluminium, the manufacturing industry is witnessing a paradigm shift. The innovative properties of this material, coupled with the expertise of companies like ABC Manufacturing, have paved the way for groundbreaking solutions across various sectors. As technology continues to advance, Extruded Aluminium will undoubtedly play a crucial role in shaping the future of manufacturing, propelling industries towards a more sustainable and efficient tomorrow.

Discover the Versatility of 80 X 40 Aluminum Profiles for Various Applications

As the construction industry continues to grow, the demand for high-quality building materials becomes more significant than ever. One of the crucial components of modern infrastructure is the aluminium profile, a structural material that plays a crucial role in ensuring the durability and functionality of various building structures. Recently, a leading manufacturer had introduced the 80 X 40 Aluminium Profile, which is garnering a lot of interest in the construction industry. Although aluminium profiles are not new to the market, this particular product's features and qualities are making the difference.The 80 X 40 Aluminium Profile is a structural material that has numerous applications in construction and other industries. It is made of high-quality aluminium, which is known for its lightweight, durability and strength. The product measures 80mm by 40mm and stands out among other profiles because of its T-slot design that allows for easy and flexible assembly. The design also offers numerous mounting options that eliminate the need for drilling and tapping. One of the significant advantages of the 80 X 40 Aluminium Profile is its versatility in terms of usage. It can be used in a broad range of applications ranging from residential, commercial, and industrial construction. Its strength and durability make it ideal for structural building applications, while its flexibility allows for the creation of custom fixtures and fittings for commercial and industrial use.In addition, the profile's lightweight nature and ease of assembly make it ideal for applications in the automotive and aerospace industries. Its T-slot design allows for the development of customized packaging and transportation systems that can reduce costs and improve efficiency.The 80 X 40 Aluminium Profile is manufactured by a leading company in the construction industry that has made a name for itself by producing high-quality building materials. The company has a reputation for excellence and has a team of highly skilled professionals that are dedicated to providing customers with the best services. From the company's introduction statement, the manufacturer has a well-equipped production plant that uses modern machinery and technology in the production process. The company has made significant investments in research and development to ensure that its products meet stringent quality standards. The company's commitment to excellence is reflected in its quality assurance practices. The manufacturer has implemented stringent quality control measures that ensure that products are regularly tested to meet customers' quality requirements. The company also has a dedicated customer service team that provides clients with technical assistance, advice, and support related to the products offered.The introduction of the new 80 X 40 Aluminium Profile demonstrates the manufacturer's commitment to innovative and quality products. The product's unique T-slot design and versatility make it ideal for various applications in the construction, automotive, and aerospace industries. The company's reputation for excellence and commitment to quality makes it a reliable supplier of high-quality building materials.Overall, the 80 X 40 Aluminium Profile is an excellent addition to the construction industry. The product's superior quality, strength, and versatility make it a valuable asset to any construction project, providing durability, functionality, and easy assembly. The manufacturer's investment in advanced technology and quality assurance practices ensures that customers receive the best and reliable products on the market.